The majority of the houses in and around the City of Sandy Oaks (and the community of Sandy Oaks 3 miles away) are mobile homes. These homes vary in manufacturing quality, but all older mobile homes have something in common: Polybutylene pipes.

Polybutylene

Polybutylene is a type of plastic resin. It was used from the 1970’s to the 1990’s to make plumbing pipes because it was less expensive than other materials and easier to install. Polybutylene pipes are usually gray and are flexible to a degree. They often have copper rings that connect them to other pipes, although there are other methods.

The problem with Poly B pipes is that the plastic resin begins to break down over time. It is suspected that chlorine in the water does this. When the pipe material breaks down it then can crack, split, or burst. Poly B pipes often form a hole the size of a small pin-prick, but can also easily split or burst once they’re worn down.

Poly B is so bad that a class action lawsuit was settled for $1 billion dollars.

Poly B in Mobile Homes

Poly b is especially bad in mobile homes for a number of reasons.

The sub-floor in mobile homes is almost like compressed sawdust. When it gets wet it swells, and once it dries it turns into powder.

Pipes in mobile homes have to be placed between the sub-floor and the insulation under the home. This keeps the pipes insulated as well as out of the way when being transported. However, it also means that a leak can go undetected for a while and can cause a lot of damage to the floor and the insulation that protects it.

Options For New Pipes

Copper is the ultimate pipe material. The pipes and fittings can be melted together to form a strong bond that will make a leak proof system for a very long time. A copper pipe can be a problem when water freezes, but that might only happen once every 2 years in South Texas.

The downside to copper pipes is they are ultra expensive compared to other options.

CPVC is a second option. It’s less expensive than copper, and easy to install.

The downside to CPVC is using glue and glue-primer to connect pipes and fittings. Because mobile homes are rather long, multiple pipes have to be connected to one another which means more connections that can go wrong in the future. Also, frozen water can cause a pipe to burst or break.

PEX is similar to Poly B, but is made from a different type of plastic called polyethylene. PEX pipes are slightly thicker (in the material, not the diameter) than Poly B pipes, but are still flexible. When water freezes, PEX expands to 3 times its size. It also typically comes in 3 different colors, red, white, and blue, so you can color code your pipes to hot/cold.

The two greatest benefits to PEX is that it is extremely easy to install and comes in lengths of 50′ or 100′. The long length means less connects, less fittings, and less places that could potentially fail/leak. Having no messy glue or heating torch necessary is helpful too.

Wait, isn’t PEX just multicolored Poly B?

In a lot of ways they are very similar, but what they’re made of and how they’re attached are very different.

While millions of homes in the United States were being built with Poly B pipes installed, homes in Europe were being plumbed with PEX. The PEX pipe doesn’t have a history of major class action lawsuits.

PEX is even being installed to heat the floors of homes in areas that get cold winters. Hot water is pumped through the pipes to heat the homes.

Plan It Out

PEX was my piping of choice because of its low cost and easy installation. There was a lot of decision making required before I ever started or bought the materials.

Clamps and Fittings

PEX has different types of clamps to connect pipes to fittings. Clamps are rings that slip over the pipe. It is important to choose your clamp style ahead of time because a special clamping tool is needed and you’ll be using it on every fitting and every connection.

Personally, I went with a cinch ring style clamp. I was at a lumber store trying to decide which clamp and a man who builds homes in the Waterwood area was standing right next to me and told me they were the best. The tool can be used for different pipe thicknesses too, while other systems need different tools for different thicknesses.

Most fittings are male, which slip into the pipe. To clamp the pipe to the fitting, first a clamp must be place over the pipe, then the fitting is inserted into the pipe, and then the clamp is tightened.

There are female fittings, however, which do not require any clamps or extra tools at all. They’re called “push to fit” fittings because all you have to do is shove the pipe into them. The upside is you don’t have to buy expensive tools. The downside is that push-to-fit fittings are expensive and the cost ads up if you’re re-plumbing your entire house.

Layout

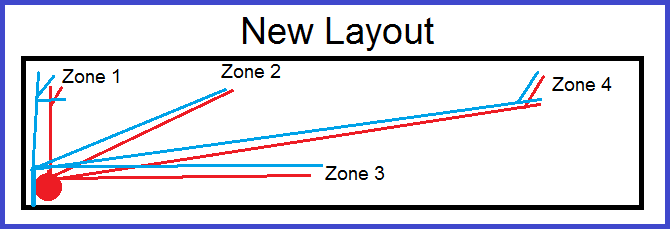

Most mobile homes have the same plumbing layout. A long pipe, usually 3/4″ thick, runs the length of the house. This pipe feeds water to all the other areas of the house and needs to be 3/4″ so that someone taking a shower on one end of the house will still have good water pressure while a washing machine in another area is being started.

Because PEX is inexpensive and is flexible, a manifold can be installed. A manifold allows for the split off of multiple pipes from one location. These pipes are usually 1/2″ and are directed toward the area they are needed. The great thing about a manifold is that a shut off valve can be installed for each individual pipe.

So in the future, if you’re installing a new kitchen sink, you won’t have to turn off the water to the entire house, only the water to the kitchen area. If your new kitchen sink is not working because of a defect and you have to go without a sink for another day (happened to me) then you still have water throughout your house.

A manifold system is more expensive, however, because more pipe is needed.

Colors

PEX typically comes in patriotic colors of red, white, or blue. The concept is for red and blue to be used for hot and cold lines respectively.

Hypothetically, one color could be used for the entire re-plumb, which would save a lot of money. But having color coded pipes is really useful both in the install and for the future.

Installing PEX Pipe

Unless you are wanting your new pipes EXACTLY where your old pipes are, you can leave your old pipes installed and the water left on while the new pipes are installed.

I never liked the idea of my pipes being able to ruin my floor or my insulation, so I chose to install them underneath the insulation, thus outside the home. This requires more money to be spent on pipe insulation, but it means my house is protected somewhat better. It also made installation super fast and super easy.

PEX comes coiled and can be a real pain to straighten out when you’re underneath your house and covered in sand. I suggest you measure how much you need, then straighten out that length while out in your yard. The pipe can then be feed into where you need it.

Whichever option you choose, traditional or manifold, PEX needs to have some slack in it so that it can expand and contract during different seasons/temperatures.

Put the pipes into place before cutting anything and before attaching fittings. If you don’t, then you might have a fitting pointing a different direction than where you want your pipe.

From my work in woodworking, I’m pretty good at eyeballing a 1/8″ to 1/4″ distance, which is the space a clamp needs from the end of a pipe. However, for those who aren’t adept at this, I tested using a piece of wood to measure the space, and it worked out well. To make your own, take a scrap 1×4 and drill a hole 1/4″ deep with a forstner or spade drill bit that is slightly wider than your pipe size. This tool can be used to mark where the pipe is 1/4″ long and you won’t have to mess with a measuring tape while covered in sand and in the dark.

Mobile homes are typically built on 2 steel beams that run the length of the house. This is why the plumbing for the house is usually inside the floor, because the pipes can be placed over the beams in the manufacturing process. If the pipes are not in the floor, and are outside under the insulation, it means they will have to go under the beams.

There are different options to go around the beams. One would be to run the pipe to the beam and then make a large “U” with 4 different 90 degree fittings. For me, that meant 8 more (2 per fitting) areas where something could fail in the future.

A second option is to bend the PEX and fit it into a piece of plastic (sold in the plumbing section) that holds the pipe in place and gradually runs it at a 90 degree angle. It doesn’t pinch the pipe, just holds it.

A third option is to just run the pipe directly under the beam to where it is needed and allow for a natural U curve, but to also have it held in place.

Notes

This is not a complete guide to re-plumbing a house. Other things need to be taken into consideration. For example, a PEX pipe that leads to a water heater needs to have 18″ of copper pipe between it and the heater.

Do a fair amount of research before you ever start spending money and time. And follow building codes so that your plumbing job is acceptable. Otherwise, you might run into trouble if you try to sell your house.

Comments are closed.